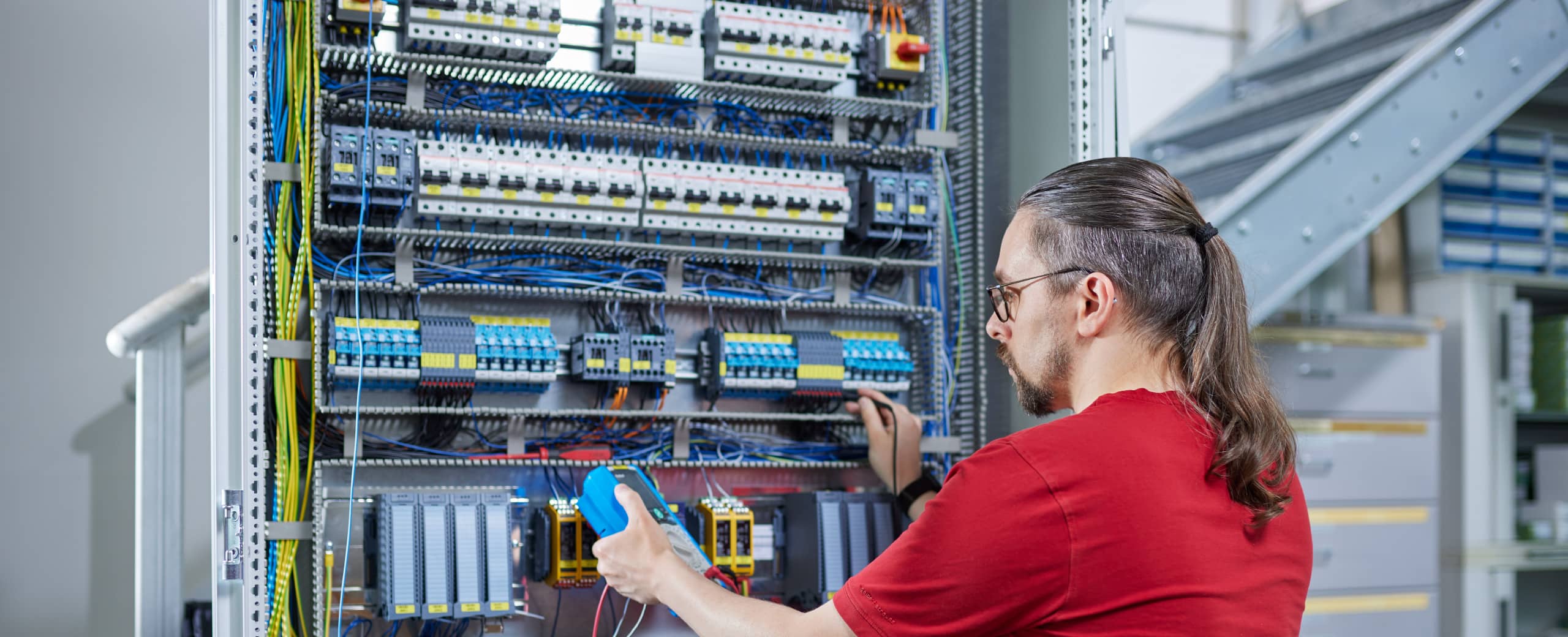

Das Thema Automatisierung verbindet weltweit Techniker aller Branchen, die unterschiedliche Sprachen sprechen und mit verschiedenen Programmiersprachen komplexe Software entwickeln, Steuerungen aufbauen und in Betrieb nehmen. Wir von CEP in Dresden sind mit der rasanten Technologieentwicklung seit über 30 Jahren stetig gewachsen, technisch up-to-date und weltweit unterwegs.

Wir freuen uns auf Ihre Automatisierungsaufgabe – eine Lösung ist garantiert in Sicht!

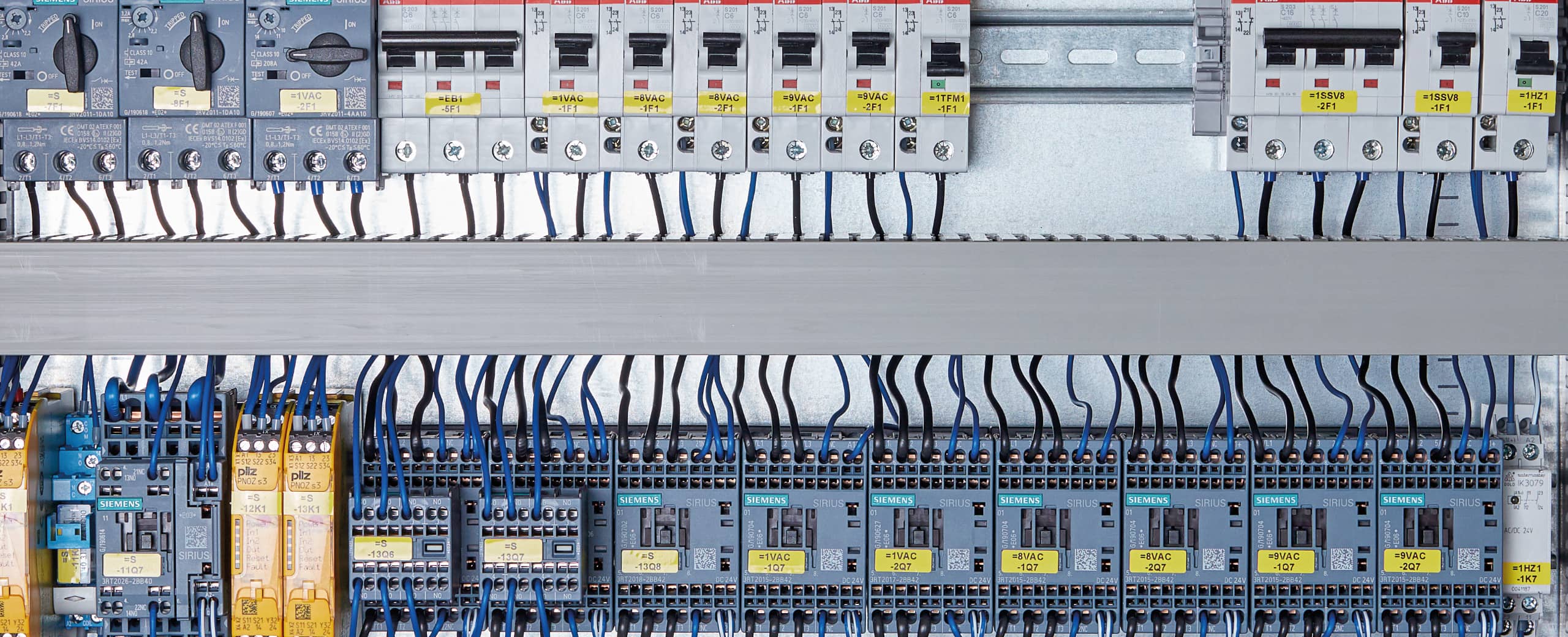

CEP-Kernkompetenzen

Darüber hinaus sind wir für jede Automatisierungs- und Steuerungsaufgabe ansprechbar.

Jobs und Karriere bei CEP

Willkommen in einem Team von großartigen Fachleuten, mehr noch, großartigen Menschen!

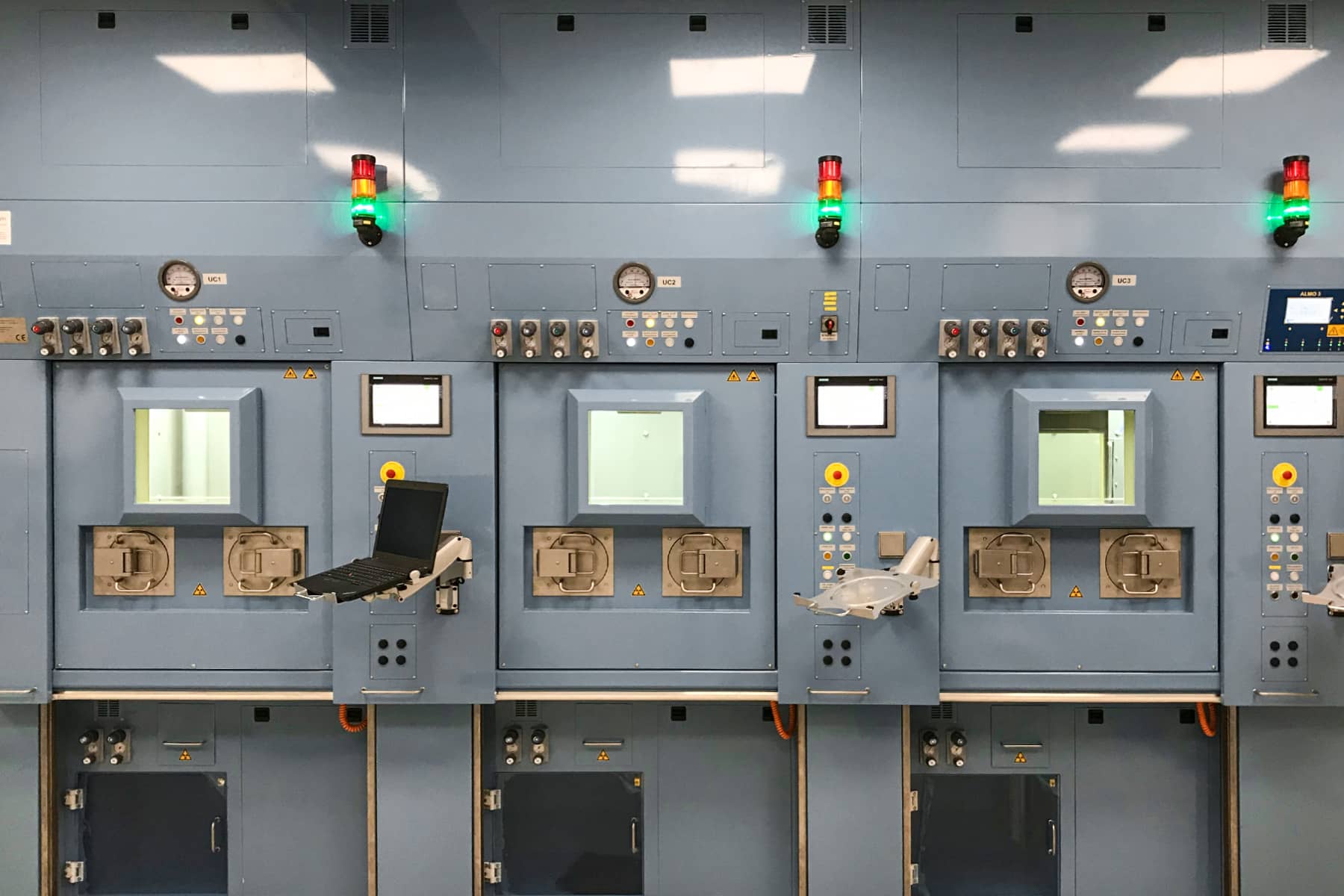

Die wesentlichen Tätigkeitsfelder Ihrer Arbeit oder Ausbildung bei CEP umfassen so spannende Fachgebiete wie z. B. die präzise Steuerung von Theaterbühnentechnik, die Arbeit an großen Vakuumbeschichtungsanlagen und komplexen Pharma-Anlagen bis hin zu den »Schraub-Robis«, innovativer Schraub-Roboter-Technik. Als Teil unseres Teams entwickeln und produzieren Sie in Dresden oder sind für die Montage und Inbetriebnahme weltweit unterwegs.

Der Schlüssel zum Erfolg sind nicht Informationen. Das sind Menschen.